New Main Wharf North - Port Nelson

major upgrade to key regional port

When the $20m redevelopment of Main Wharf North, Port Nelson was awarded to McConnell Dowell as a design and construct contract, there was a serious earthquake resilience issue to contend with. The new wharf structure consisted of a 100m-long new suspended deck on steel tubular piles with all associated works required. This new berthing facility takes larger vessels and is located further away from residential properties to reduce noise from the port. To achieve this involved complex issues. And that’s where we got involved.

McConnell Dowell engaged specialist subcontractor Wagstaff Piling to undertake the sheet piling and cutter soil mixing ground improvement works behind the wharf, to improve earthquake resilience.

how did we optimise, earlier?

Andy O’Sullivan were engaged by Wagstaff Piling to produce detailed design for ground improvement and sheet pile retaining wall, including being responsible for the global stability of the backland area and the stability of the revetment tie-in areas.

Overlapping 800mm wide by 12m deep cutter soil mixing panels were installed to prevent seismic liquefaction-induced lateral spreading. This was an issue on people’s minds after the devastating Canterbury earthquake.

This was a tricky design challenge, with the ground improvement being unique – to also provide lateral restraint to the main wharf in a major earthquake. But it also allowed for significant design optimisation of the main wharf piles.

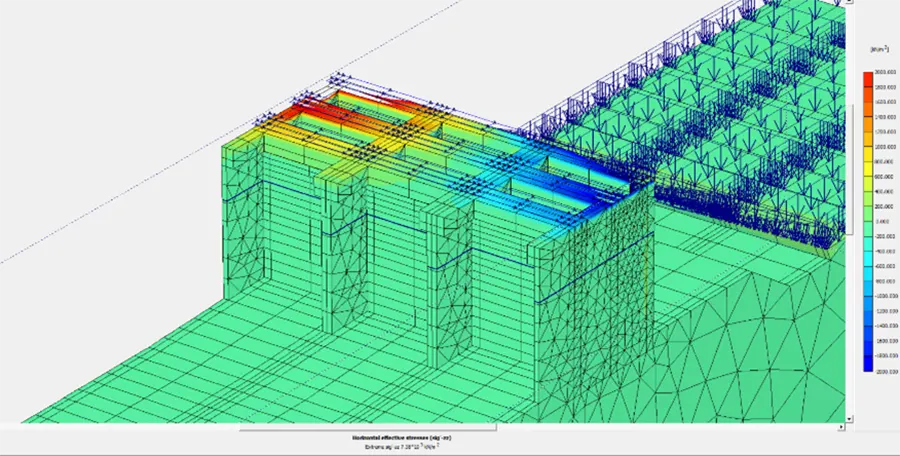

The design of this complex soil/structure interaction involved sophisticated state-of-the-art 3D finite element modelling. This ensured full stress/strain compatibility between our geotechnical design and the structural design for the main wharf, which was undertaken by lead consultants Beca.

We also needed to ensure the ground improvement could adequately transfer thermal expansion and shrinkage loads associated with the overlying reinforced concrete slab through the shear keys that connected the slab to our underlying ground improvement. Andy and the team analysed the concrete slab/ground improvement interaction using fully-coupled thermal finite element modelling.

We optimised the solution, saving cost, by clearly demonstrating that despite the very high loading imposed on the ground improvement, there was no need for additional steel reinforcement to meet the stringent Principal’s requirements.

Once again we overall optimised a ground improvement solution, saving the contractor money and delivering a great solution for the client.

3D Finite element modelling of ground improvement

“Design and detailing of the soil – structure interaction for the Main Wharf North project was a considerable challenge for all involved. The ground improvement was required to stabilise the existing fill and alluvial soils, provide the majority of the lateral restraint for the entire wharf and back span slab in a highly seismic zone, all without excessive restraint of thermal and shrinkage actions. Andy and his team provided strong leadership in this complex interface, relentlessly driving efficiency and value in the solution.”